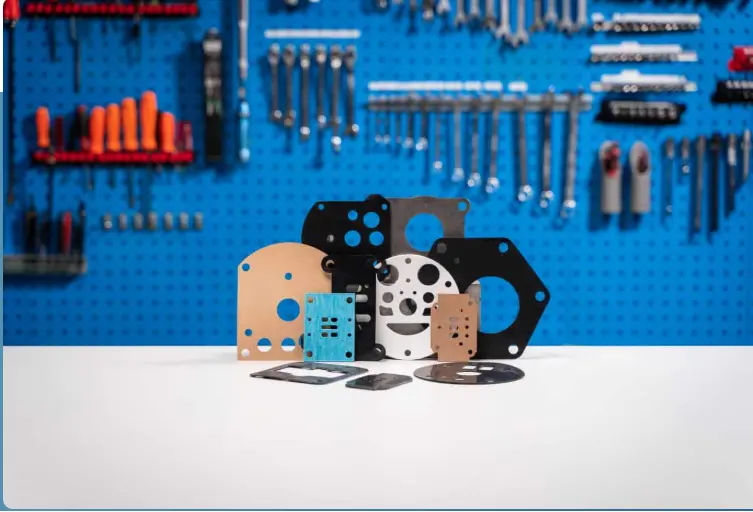

Air-operated double diaphragm (AODD) pumps run reliably only when the right wear parts are used. On this page you can browse AODD pump spare parts by part type – air valves, diaphragms, balls, seats, O-rings, gaskets, kits and more. We supply OEM-compatible replacement parts for major AODD brands, helping you keep your pumps running while controlling maintenance cost and avoiding long OEM lead times.

Most repair kits for AODD pumps combine several of these items in one set – typically diaphragms, balls, seats, gaskets and O-rings – all matched to a specific pump model and material.

The air valve (air distribution system) is the "heart" of an AODD pump. If it sticks or wears, the pump can stall, cycle irregularly or fail to start. We offer AODD air valves and air-side repair kits including gaskets, O-rings and internal sliding parts, suitable for many pump brands and sizes. Using a fresh air valve kit restores smooth shifting, reduces icing problems and helps the pump reach its designed flow and air consumption.

Check balls control the flow in and out of each diaphragm chamber. Worn or swollen balls cause loss of prime, reduced capacity and backflow. Our range covers AODD pump balls in SS316, PTFE, Santoprene®, Buna-N (NBR), EPDM and other materials to match the chemical and temperature of your application. Correct ball material and finish help to achieve tight sealing, long service life and low pulsation.

Diaphragms separate the air side from the liquid side and are usually the most critical wear part in an AODD pump. We supply AODD diaphragms in PTFE, rubber and composite constructions to suit abrasive, corrosive or high-temperature duties. Material options include PTFE, PTFE-backed, Santoprene®, Buna-N, EPDM, FKM and PU, depending on brand. Correct diaphragm choice improves run time between failures and reduces risk of leakage to the air system or product contamination.

Gaskets seal the joints between manifolds, chambers, center block and covers. Over time, they can take a set, crack or get damaged when pumps are opened. We provide gasket sets for AODD pumps, cut from compatible elastomers or PTFE-based materials for chemical resistance. Replacing gaskets during every strip-down helps ensure leak-free operation and stable suction performance.

Repair kits bundle everything needed for a planned overhaul. Wet-side kits normally include diaphragms, balls, seats, gaskets and O-rings for the fluid path, while air-side kits cover air valve components, air gaskets and dynamic seals. Using a kit saves time on part selection and ensures that all critical items are replaced at the same time, restoring pump performance close to new.

Exhaust mufflers (silencers) reduce the noise from the air outlet of an AODD pump and can help manage ice formation on the exhaust. Damaged or clogged mufflers increase back-pressure and can affect pump efficiency. We offer replacement mufflers and muffler elements suitable for plastic and metal AODD pumps so you can keep noise levels and air back-pressure under control.

O-rings are used in many sealing points: manifolds, valve seats, air valves and sometimes diaphragm plates. Even a small O-ring leak can cause air or liquid loss and unstable operation. Our program includes AODD pump O-rings in NBR, EPDM, FKM, PTFE-encapsulated and other compounds, selected according to chemical, temperature and pressure. Changing O-rings whenever the pump is opened is a low-cost way to prevent future leaks.

The piston or inner shaft connects the two diaphragms and transmits motion from the air valve to both chambers. Wear on the piston, guides or seals can lead to uneven stroke, noise and premature diaphragm failure. We supply pistons and related components for many AODD pump designs, allowing you to restore correct alignment and smooth reciprocating motion during a major overhaul.

Valve seats work together with the balls to form a tight check valve. Scratched, eroded or chemically attacked seats reduce sealing and allow product to slip back, cutting flow and efficiency. Our AODD valve seats are available in metal and plastic materials – such as stainless steel, aluminium, polypropylene and PVDF – so you can choose the best combination for your fluid, solids content and temperature.

Center shafts and connecting shafts carry the diaphragms and transmit the reciprocating movement across the pump. Corrosion, wear at the diaphragm mounting face or bending from mis-installation can all shorten diaphragm life. We offer replacement AODD shafts machined to correct OEM dimensions so that diaphragms seat properly and the pump runs true. Installing a new shaft during a full rebuild can significantly extend the time between failures.

Our technical team can help you identify the exact replacement parts for your AODD pump model. Get OEM-compatible parts with faster delivery and competitive pricing.